- Home

- About us

- Products

Products

Crushing Equipment

- Jaw crusher

- Impact crusher

- Multi-cylinder hydraulic cone crusher

- VSI sand making machine

- Single cylinder hydraulic cone crusher

- High efficiency fine crusher

- 2-Roll crusher

- Compound crusher

- Hammer crusher

- Spring cone crusher

- Small mobile diesel engine jaw crusher

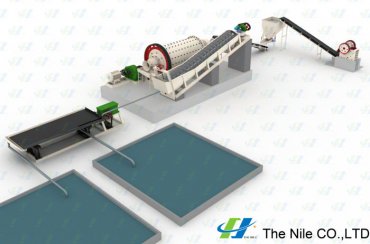

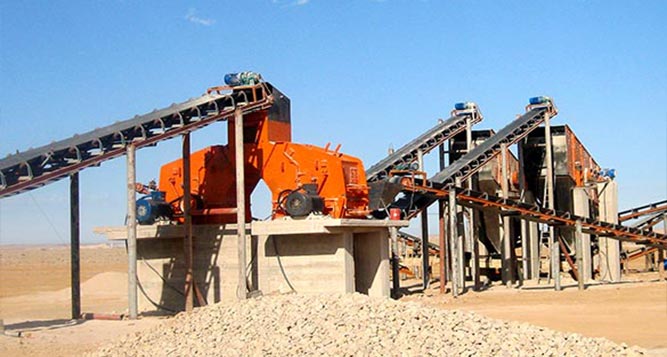

- Granite / Basalt Crushing Processing Line

- Electronic waste recycling machine/Circuit board

- Limestone Crushing Processing Line

- Symons cone crusher / Combined cone crusher

Grinding Equipment

Mineral Processing Equipment

- Gold Carbon In Leaching Plant

- Analytical electrolysis machine

- Pulp thickener

- Double impellers leaching stirred tank

- Magnetic Separator

- Gold dressing agent

- Disc vacuum filter

- Jigging Machine

- Flotation machine

- Wet process magnetic separator

- Centrifugal gold concentrator

- Plate and Frame Filter Press machine

- 6-S Shaking table

- Adsorption and Elution Column

- Coconut shell activated carbon

- Spiral chute

Screening & Feeding Equipment

Mobile Crushing Plant

Other Equipment

Accessories

- Jaw plate of jaw crusher

- Hammer

- Hammer plate of the impact crusher

- Concave / Crushing wall / Rolling mortar wall / M

- The roller of roll crusher

- Ball mill steel ball

- High manganese steel ball mill liner

- chrome alloy ball mill liner

- Rubber liner

- Flotation machine impeller

- Screen

- Conveyor belt

- The idler of belt conveyor

- Filter bag

- Solutions

- News

- Case

- Service

- Contact