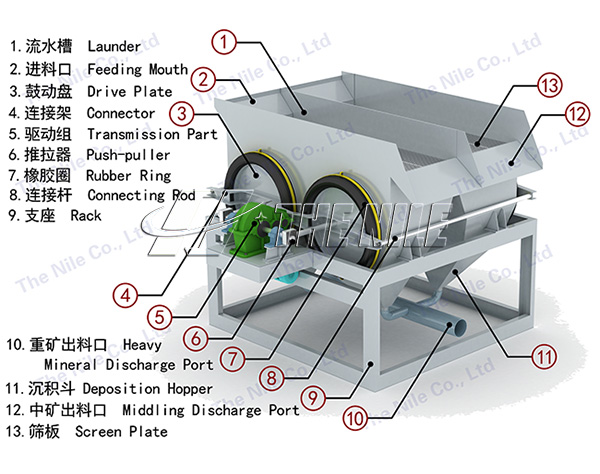

Product introduction

Jigging machine belongs to deep groove sorting operation, it uses water as the mineral processing medium, use the selected mineral and gangue proportion difference carries on the separation. Many of the jig is diaphragm type, stroke and Chong time according to the proportion of selected minerals, can be flexible adjustment, widely used in tungsten, tin, gold, red iron, brown iron, manganese, titanium, antimony, lead, tantalum, niobium and other gravity beneficiation.

Working principle

Jigging machine belongs to the deep groove type of equipment. All jigging machines have jig chambers. Encourage the movement of the flow of the institutions and products to expel the body. Jig indoor sieve plate by punching steel plate, woven iron screen or grate, water flow through the sieve plate into the jig room should make the bed raised a small height and slightly loose state, the density of the particles due to local pressure and settlement speed of large and into the bottom, small density of particles are transferred to the upper level. When the water flow drops, the fine particles with high density can also enter the lower layer through the gradual close bed gap to supplement the layering according to density. In the early years, the mechanism that agitated the water flow used a piston. The piston chamber was located beside the jigging chamber, and the lower part was connected. The eccentric link mechanism moved the piston up and down.