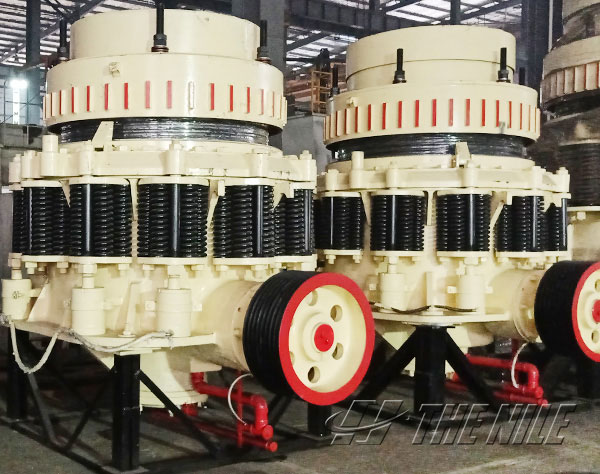

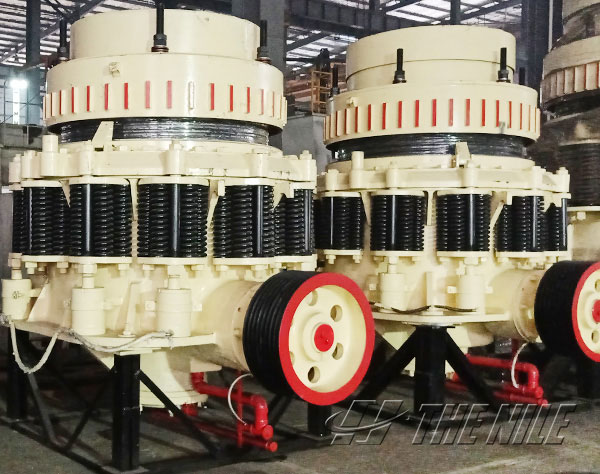

Crusher is essential machinery in mining, construction, railway, highway and other industries. It can crush various ores and rocks with medium and medium hardness. The wear-resistant accessories with good quality play an important role in the working process of the crusher, which can improve the crushing efficiency and the service life of wear-resistant accessories and reduce production costs. This article will list the factors affecting the service life of the crushing wall and rolling mortar wall of the cone crushing station.

1. Stone powder content and stone humidity

In the work of cone crusher, if the content of stone powder is high and the humidity is high, the material will easily adhere to the inner wall of crushing wall and mortar rolling wall when crushing, so as to reduce the production efficiency and service life of the cone crusher, and even corrode the crushing wall and mortar rolling wall.

Therefore, when the content of stone powder is high, it must be processed with a vibrating screen before crushing, so that the situation of excessive fine powder can be avoided. When the humidity of material is high, measures should be taken to reduce the moisture content before crushing, such as mechanical drying or natural drying.

2. Hardness and particle size of stone

Stones of different hardness have different degrees of wear on the crushing wall and rolling mortar wall of the cone crusher. The higher the hardness of the material, the greater the impact load that the crushing wall and rolling mortar wall will bear in production, and the service life will be shortened accordingly. When the hardness of the stone is same, the larger the particle size of the stone entering the crushing cavity, the more serious the liner wear, so the service life will be shortened.

3. Feeding mode

The feeding mode of cone crusher will also affect the service life of crushing wall and mortar rolling wall. If the feeding device of crusher is not installed properly, or too much material is put into the crushing cavity, it will cause uneven feeding, material blocking in the crushing cavity and other faults, which will make the crushing wall and mortar wall bear too much pressure, so as to increase the wear of inner wall, damage the lining plate and reduce the service life.

4.The quality of the crushing wall and rolling mortar wall

The above three points are all external factors, and the most important factor affecting the service life of crushing wall and mortar rolling wall is its own quality. At present, the crushing wall and rolling mortar wall of the cone crusher on the market are generally made of high manganese steel, and casting defects that affect the performance are not allowed. With the development of science and technology, the performance of wear-resistant materials has been continuously improved. On the whole, it is necessary to choose a material that can quickly harden the surface under the action of impact load to form a hard and wear-resistant surface, while still maintaining the original toughness of the inner metal, so as to improve the service life of the crushing wall and mortar rolling wall.

The above are the four factors that affect the service life of the crushing wall and rolling mortar wall of the cone crusher. During the use of the cone crusher, in addition to the crushing wall and the rolling mortar wall, we should also pay attention to the use of other parts of cone crusher and do regular maintenance of the cone crusher to ensure the normal and efficient operation of the crusher.