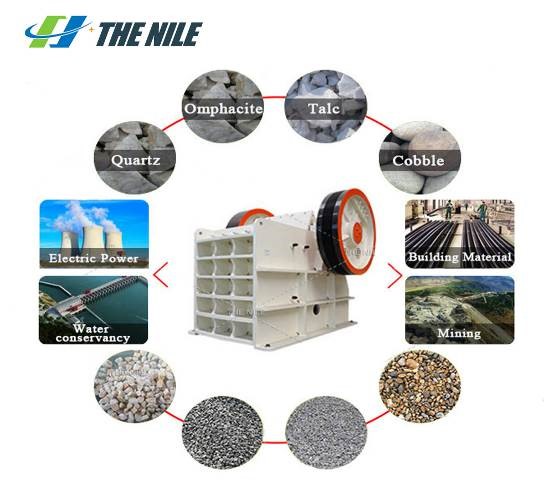

Jaw crusher is widely used in metallurgy, building materials, chemical industry, coal and other industrial sectors. The machine is suitable for coarse, medium and fine crushing of various materials with Mohs hardness below 7 grade. When used for fine crushing, should use fine jaw crusher. Applicable materials for jaw crusher: pyrite ore, phosphate rock, barite, celestite, calcium carbide, coke, limestone, etc.

In order to ensure the normal operation of the jaw crusher, in addition to the correct operation, planned maintenance must be carried out, including daily maintenance inspection, minor repair, medium repair and overhaul.

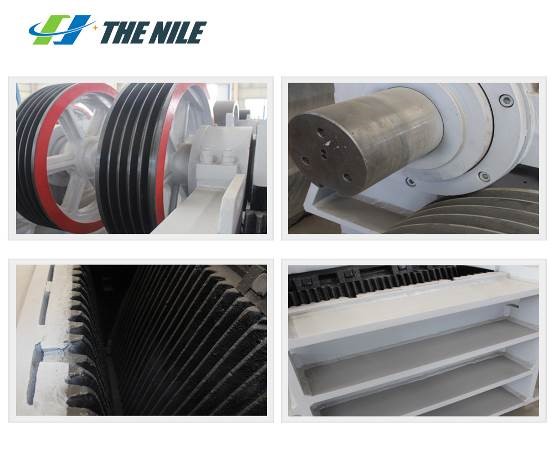

1. Minor repair: The main contents include inspection and repair adjustment devices, high-speed discharge port clearance, and turning or replacing the worn liner. Overhaul the drive section, lubrication system, and oil replacement. The minor repair cycle is about 1-3 months.

2. Medium repair: In addition to all the work of minor repairs, it also includes replacement of thrust plates, liners, inspection and repair of bearing bushes. The period of medium repair is generally about 1-2 years.

3. Overhaul: In addition to all the work in the middle repair, it also includes replacing or turning the eccentric shaft and the moving jaw shaft, casting the babbitt alloy on the upper part of the connecting rod head, and replacing or repairing the worn parts. The period of overhaul is generally about 5 years.

Preparation for the jaw crusher before starting:

1. Care should be taken to check whether the lubrication of the bearing is good and whether there is sufficient grease at the joint of the bracket inside the bearing.

2. Care should be taken to check that all fasteners are fully tightened.

3. Whether the protective device is good or not, it should be eliminated immediately.

4. Check for any ore or other debris in the crushing chamber. If any, remove it immediately.

Starter of the crusher:

1. After inspection and proof that the machine and transmission parts are in normal condition, they can be started.

2. The jaw crusher can only be started without load.

3. After starting, if there is any abnormal situation, stop immediately and wait until the cause is removed to avoid the hidden danger before starting again.

Maintenance and use of the jaw crusher:

1. After the crusher is in normal operation, it can be fed.

2. The material to be crushed should be evenly added into the crushing chamber, and side feeding should be avoided to prevent sudden load or unilateral sudden increase.

3. Under normal working conditions, the temperature rise of the bearing should not exceed 35 °C, and the maximum temperature should not exceed 70 °C. Otherwise, stop immediately and find out the cause to eliminate it.

4. Before stopping, the feeding should be stopped first, and the motor can be turned off after the crushed material in the crushing chamber is completely drained.

5. When using, if the machine is stopped due to blockage of material in the crushing chamber, the motor should be turned off immediately, and the material must be removed before it can be used again.

6. The end of the jaw is worn and then turned over.

Lubrication of PE jaw crusher:

Oil-free bearings:

1. Always pay attention to the lubrication work of the friction surface in time to ensure the normal operation of the machine and prolong the service life.

2. The grease used in the jaw crusher should be determined according to the location, temperature and other conditions. Generally, calcium-based, sodium-based or calcium-sodium-based greases can be used.