Introduction of Spiral Classifier

Spiral Classifier also can be called spiral separator, screw classifier or screw separator. lt is made up a closed-loop with ball mill, allows the fine ore to float in the water, while coarse ore sinks to the bottom, and widely used in the separation for metal ore-dressing, non-metal ore-dressing and other operations with ball mills.

Spiral classifier is commonly used in the grinding circuit of the beneficiation as the pre-classification and inspect classification machine, and also in the ore washing and desliming operation. It is easy to form a closed cycle with the grinding machines. It has the advantages of simple structure, reliable work, and easy operation, etc.

Influencing factors of Spiral Classifier

The classification effect of the spiral classifier is affected by many factors, mainly including the particle size of the material, the density of the material, the rotation speed and inclination angle of the spiral shaft, etc. Reasonable adjustment of these factors can effectively control the classification accuracy and efficiency, thereby achieving the best classification effect.

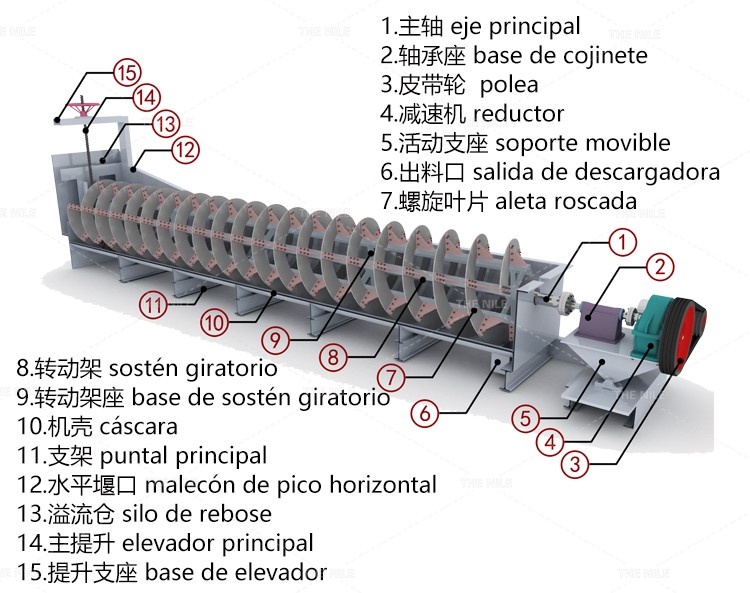

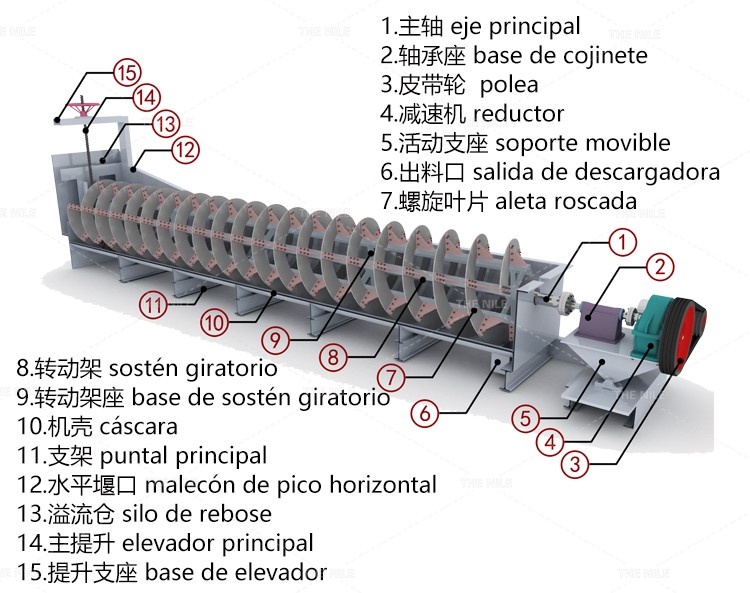

Structure of Spiral Classifier

The spiral classifier is usually composed of the main parts such as the feed port, spiral shaft, discharge port, and drive device. Its working principle is based on the fact that the material is classified according to the particle size and weight under the action of the rotation and inclination angle of the spiral shaft under the combined action of centrifugal force and gravity. As the material rotates with the spiral shaft, due to the centrifugal force, the heavier particles move outward, while the lighter particles move inward along the axial direction, and finally separate through the discharge port to complete the classification process.

Working Principle of Spiral Classifier

The spiral classifier is a grading device that uses the principle that solid particles of different sizes and specific gravities have different settling speeds in liquids. Fine ore particles float in the water and overflow, while coarse ore particles sink to the bottom of the tank. The material is pushed to the upper part by the spiral to be discharged for mechanical grading. It can filter the powder ground in the mill, and then use the spiral blades to rotate the coarse material into the mill feed port, and discharge the filtered fine material from the overflow pipe. The base of the machine is made of channel steel, and the body is welded with steel plates. The water inlet and shaft head of the spiral shaft are made of cast iron sleeves, which are wear-resistant and durable. The lifting device is divided into electric and manual types.

Features and Advantages of Spiral Classifier

High efficiency and energy saving: The spiral classifier can achieve efficient material classification and improve production efficiency without increasing additional energy consumption through reasonable structural design and precise working principle.

Precise classification: Due to the precise control of centrifugal force and gravity, the spiral classifier can achieve precise particle separation to ensure product quality and consistency.

Simple and reliable structure: The equipment has a simple structure, easy operation, low maintenance cost, high reliability and stability, and is not prone to failure in long-term operation.

Strong adaptability: The spiral classifier is suitable for the classification of materials of various particle sizes, shapes and densities, and is widely used in mining, chemical industry, food and other industries.

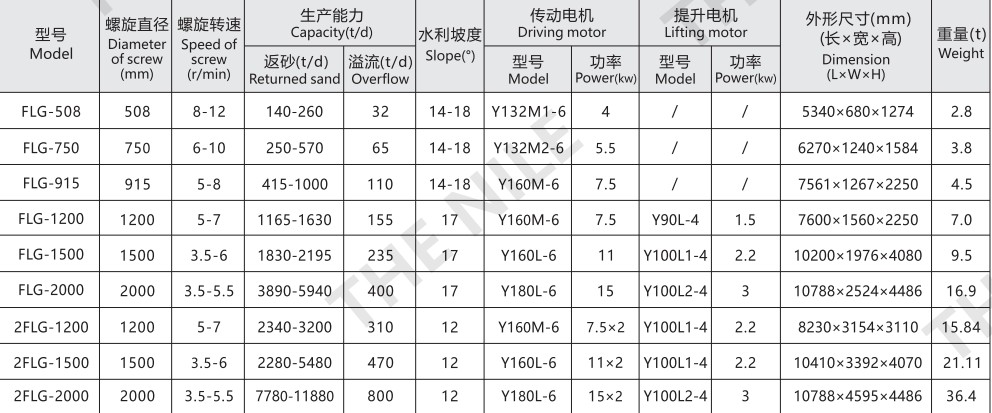

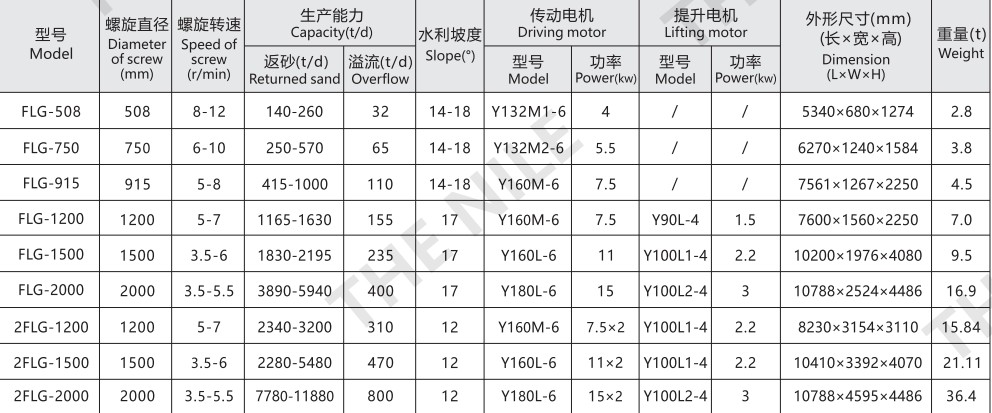

Main Technical Parameters of Spiral Classifier