The 6S mineral processing shaker is a device that uses the asymmetric reciprocating motion of the bed surface to separate light and heavy minerals. The 6S shaking table equipment can be used for different operations such as roughing, concentration, and scavenging. When processing tungsten, tin and other ores, the effective recovery particle size range of the 6S shaking table is 2-0.22 mm, and it can also be used to sort iron and manganese ores.

The 6S shaker has a large lateral slope adjustment range (0 to 10°), and its stroke is easy to adjust. The bed surface of the shaking table is flat and durable. It has good corrosion resistance, not easily deformed, and is convenient for local repairs. It can also keep running smoothly when changing the lateral slope and stroke. The bedside mechanism operates reliably, has few wearable parts, and does not spill the oil. What’s more, the shaker is reasonably priced, and consumes very little electricity.

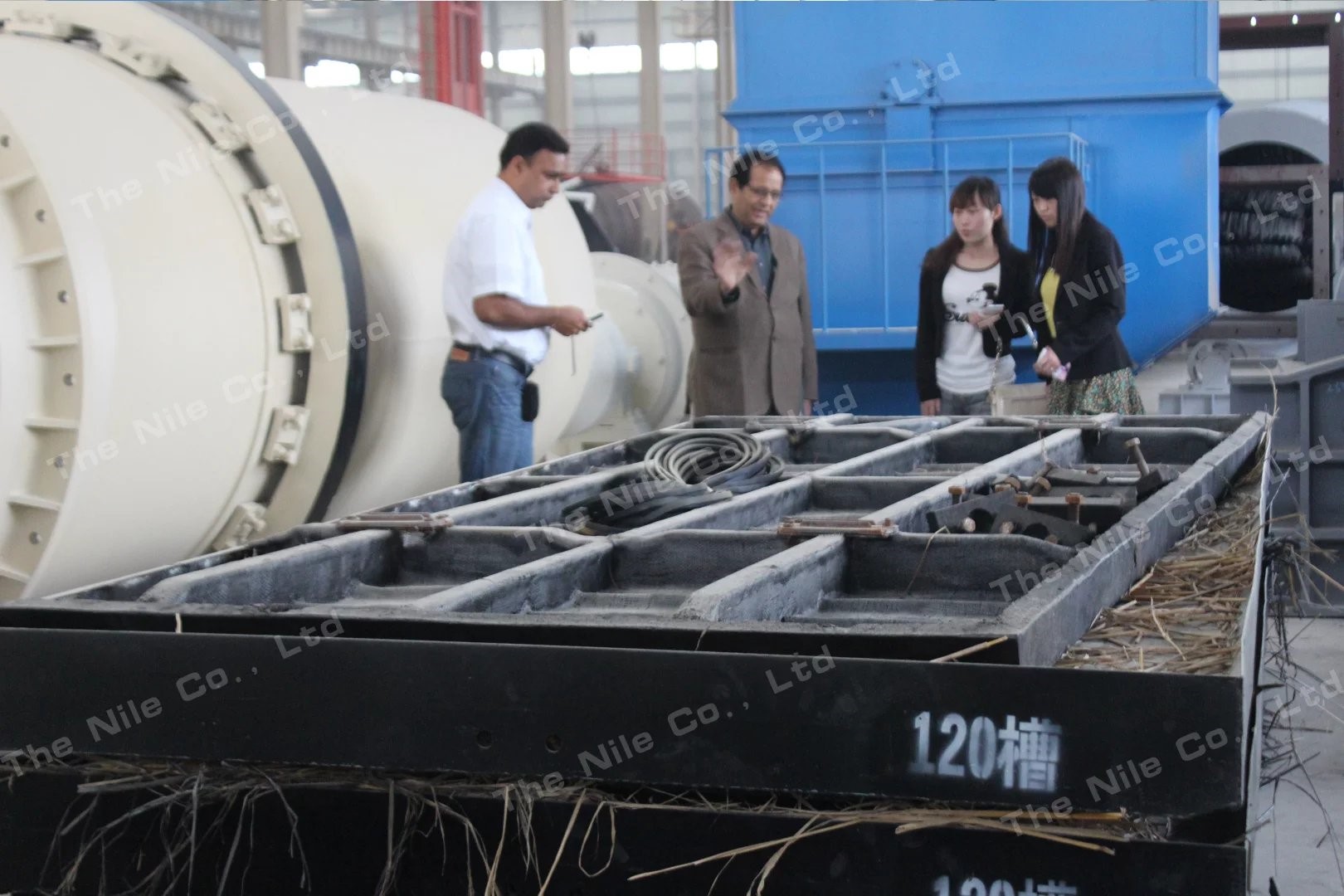

The mineral particles are fed from the ore feeding trough at the corner of the 6S shaking table bed. At the same time, the horizontal flushing water is supplied from the water supply trough. Therefore, the ore particles are subjected to the inertia and friction caused by the gravity, the lateral water flow impulse, and the reciprocating asymmetrical motion of the bed surface. Under the action of force, it is layered according to specific gravity and particle size, and moves longitudinally along the bed surface and horizontally along the inclined bed surface. Ore particles with different specific gravity and particle size gradually flow down in a fan shape along their respective directions of movement, and are discharged from different areas on the concentrate end and tailings side of the shaker, and are finally divided into concentrates, middlings and tailings.