The hardness of copper ore is 3.5-4.0, which is generally an aggregate composed of copper sulfide or oxide and other minerals. It reacts with sulfuric acid to produce blue-green copper sulfate, more than half of which is used in the power and telecommunication industries. After mining, copper mines often needs to go through various processing and then use. The following introduces the complete set of copper ore processing equipment, that is, the composition of each equipment in the copper ore process flow.

Copper ore processing equipment

1. Crusher: Copper ore, as a valuable metal ore with economic value, is usually crushed in the initial processing, so the selection and application of copper ore crusher are also relatively extensive. According to the material hardness of copper ore, jaw crusher will be selected for crushing, which has a strong crushing force. For the copper ore that needs secondary crushing, users need to choose impact crusher or cone crusher according to their actual situation. The process requires that the equipment has the characteristics of large production capacity, high working efficiency and simple operation.

2.

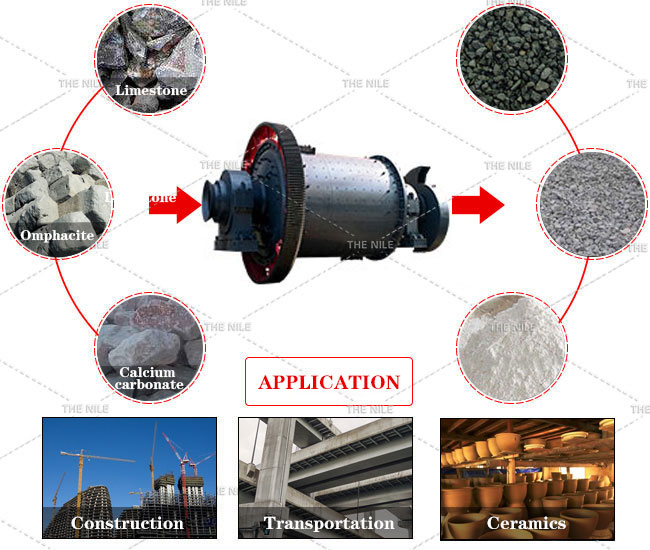

Ball mill: Most of the copper ore is used as a beneficiation material for deep processing, which will produce greater economic benefits. Therefore, ball mill is indispensable for grinding copper ore in the beneficiation process. Common types of ball mills include dry, wet, continuous and intermittent type ball mill. The user can make a reasonable choice according to the properties of the material to meet the requirements of the subsequent classification and flotation of the material.

3.

Flotation machine: In the extraction of copper ore, the most critical process is flotation, so the choice of flotation machine is very important. According to the different characteristics of gangue, subsidiary metal minerals, and copper's hydrophilicity, the flotation machine separates copper ore from it. As for the specific size of the flotation machine, users need to choose according to their own production conditions.

4. Other equipment: In order to ensure the continuity of the entire copper ore extraction process production line, classifiers, dryers, vibrating feeders, vibrating screens and belt conveyors are also needed. Nile Machinery’s engineers will provide users with reasonable equipment according to process requirements.

Copper ore processing process

1. Crushing stage: the large pieces of copper ore is preliminarily crushed. In order to make the material more uniform, it is necessary to use repeated crushing to achieve a larger crushing ratio, so that the material can enter the next stage of equipment smoothly.

2. Mineral processing stage: After the completion of crushing operation, copper ore will enter the ball mill for grinding. After grinding, it will enter the classifier for separation. Those that meet the requirements enter the next level of equipment, and those that do not meet the requirements are ground and classified again.

3. Flotation stage: In the flotation operation of copper ore, it is necessary to add the specified type and dosage of flotation reagents, and complete the flotation task after sufficient stirring, so as to meet the requirements of users.

4. Drying stage: In order to obtain copper ore with higher precision and purity, it needs to be dried. The equipment to complete the drying operation is the dryer. Therefore, this is also one of the indispensable equipment for copper mines with large water content.

If you want to know more about copper mining beneficiation equipment and processing technology, please contact us online at any time to get the most suitable and economical solution.