Firstly, it is determined by the properties and hardness of the granite. Granite is a kind of high-hardness rock, which is difficult to crush and greater abrasion on the crusher. Therefore, a reasonable crushing plan is very critical for later crushing process.

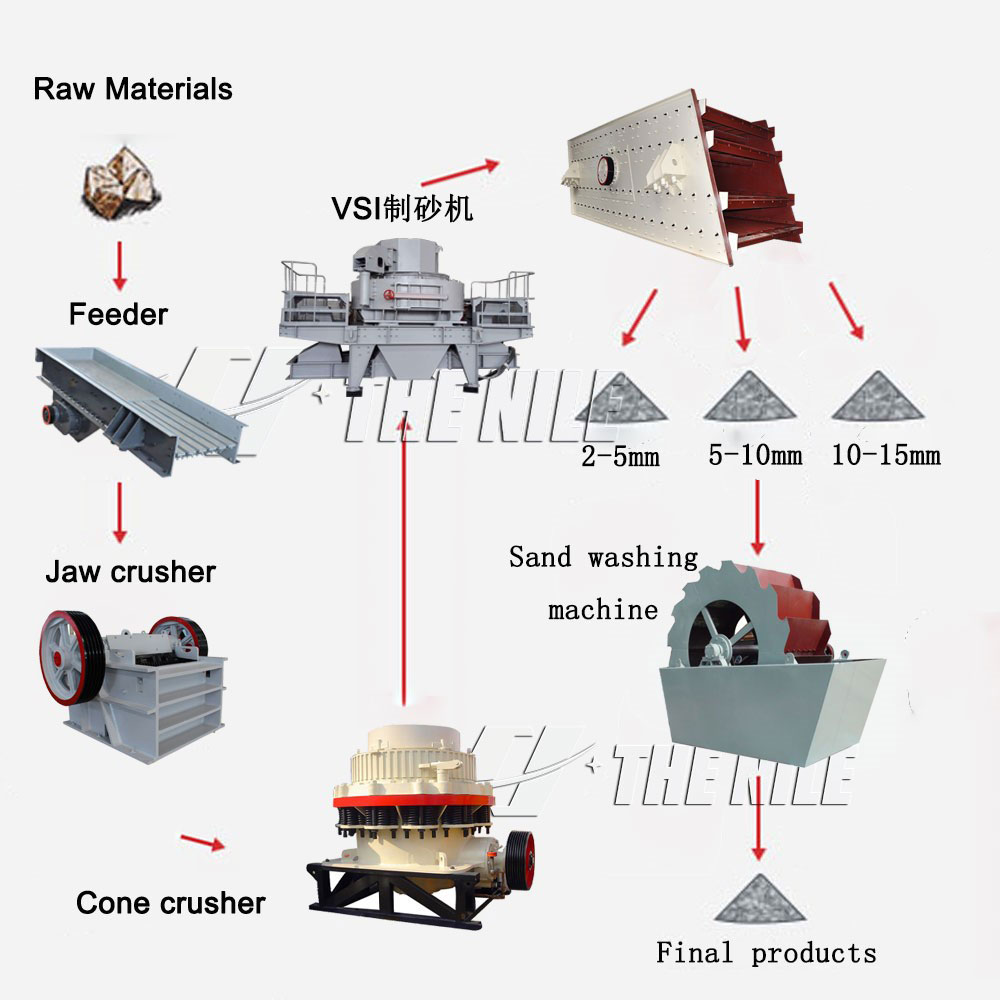

Generally, it is necessary to use jaw crusher for primary crushing , which can crush granite to 10-30cm.

Next, the choice of second crushing is different. For hard rocks such as granite, cone crusher is a more suitable choice. At present, spring cone crusher and hydraulic cone crusher are commonly used. You can choose different crusher types according to different cavity types. Such as short head type and standard type cone crusher, single cylinder hydraulic and multi-cylinder hydraulic cone crusher are used together. In this way, although the investment in the early stage is higher, the operating cost in the later stage will be much lower, so as to avoid to affect the normal production because of the frequent replacement of parts and maintenance.

The cone crusher machine can produce stone materials with different specifications such as 5-10/10-15/15-20/20-31.5mm directly.

If the crushing plant is needed to produce artificial sand at the same time, a sand making machine can be added after the cone crusher to produce 0-5mm artificial sand.

It is supplemented by other auxiliary equipments such as feeder, vibrating screen, belt conveyor, sand washing machine.

This is a relatively complete granite crushing production station. You can increase or decrease the equipment according to the actual production conditions.

The Nile will supply the rock stone crusher plant design for you!