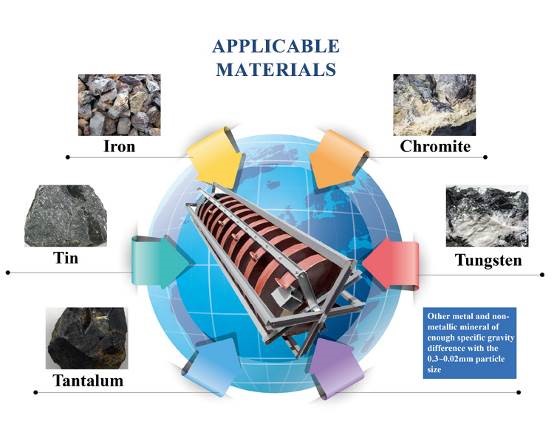

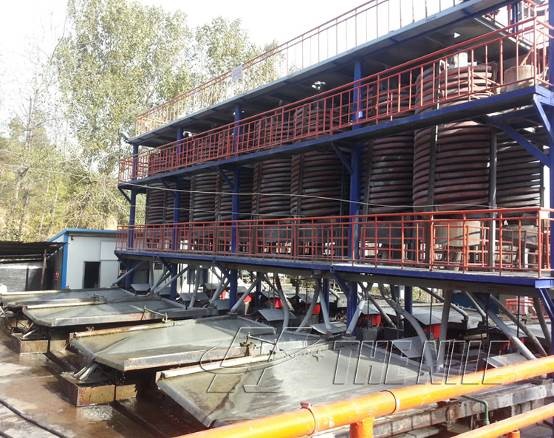

Spiral chute mainly uses the inertia centrifugal force produced by different density minerals in the spiral rotation movement to realize the separation of light and heavy minerals. Because of its simple equipment structure, low power consumption, large processing capacity and other advantages, it is widely used in the gravity separation process. This paper mainly teaches you how to improve the beneficiation efficiency of the spiral chute from its structural parameters and performance.

1. Spiral chute diameter

The diameter of the spiral chute has a direct effect on the treatment capacity and the recovery rate of the minerals in each particle. Generally speaking, the larger the diameter of the spiral chute, the larger the ore flow volume and flow rate, and the larger the processing capacity per unit time; the smaller the diameter of the spiral chute, the smaller the lower limit of the recovery particle size, and the higher the recovery rate.

2. Longitudinal inclination of spiral chute

The intersection angle of tangent line and vertical axis of spiral groove section curve is called longitudinal angle. The larger the longitudinal angle is, the faster the flow velocity of pulp is, and the greater the centrifugal force on the material is. Therefore, the small dip angle is used in the separation of fine-grained minerals and the large dip angle is used in the separation of coarse-grained minerals. The proper vertical inclination angle can make the pulp go along the tank body and improve the beneficiation efficiency.

3. Number of turns of spiral chute

The number of turns of spiral chute determines the separation distance and separation time. In the actual operation, it needs to be determined according to the properties of the selected materials and the requirements of the operation indicators. When it is difficult to separate the useful minerals and gangue minerals, a large circle number should be selected to extend the separation distance and time and improve the separation efficiency. But the number of turns should not be too much, otherwise it will increase the height of spiral chute and increase the difficulty of operation.

4. Internal surface of spiral chute

The inner surface of the chute shall be flat, uniform and wear-resistant to ensure the smooth flow of the slurry without blocking. In order to enhance wear resistance, polyurethane wear-resistant rubber is usually coated on the inner surface of FRP spiral chute.