When it comes to railways, the first thing everyone thinks of is trains. The establishment of railways makes our travel more convenient and faster. The establishment of railway tracks cannot be separated from the auxiliary role of ballasts. The ballast is the gravel used to support the rail sleepers. The ballast can evenly distribute the pressure on the upper part of the sleeper on the roadbed to reduce the vibration and noise caused by the passing train. According to experts, gravel ballast should be crushed, screened, and processed. Do you know what ore is used for railway ballast? What are the equipment for crushing ore?

1. What ore is used for railway ballast?

The passenger dedicated railway line uses sand, rock, gravel, and stable mineral materials to form a mixture that meets the requirements after being crushed and screened as the subgrade surface and track bed. They are all composed of gravel to form the basic skeleton. The main reason is that the stone is made. The ballast is low in price, easy to obtain materials, and can also play a role in cushioning and shock absorption and stabilizing the ballast bed. Granite is the material of choice for railway ballast.

2. Main crushing equipment for railway ballast

The crushing production of railway ballast is mainly divided into three stages: coarse crushing, medium crushing and screening.

1. Coarse crushing-jaw crusher

The jaw stone crusher uses squeeze crushing method to crush the material.The feed size of the jaw crusher machine is required to be more than 500mm, and it can crush various stones with a compressive strength of not more than 320MPa. Jaw crusher equipment is a commonly used crushing equipment in the mining industry. The PE series crusher can produce up to 1,000 tons per hour.

Jaw Crusher

Jaw Crusher

2. Medium crushing-cone crusher /impact crusher

Cone stone crusher and stone impact crusher adopt squeezing and impact crushing methods, the crushing feed size is below 300mm, and the discharge size is below 100mm.

Cone crusher: The squeeze crushing method is used to process materials with higher hardness.Cone crusher equipment adopts the principle of laminated crushing, so that the materials are continuously impacted, squeezed and bent in the annular crushing cavity of the fixed cone and the moving cone to complete the crushing operation; The wearing parts have long service life and high output.

Impact crusher: The impact crushing method is used for mines and rocks (such as limestone, dolomite, etc.) with a feed size of less than 300mm and a compressive strength of not more than 150MPa; The finished product of impact crusher machine is cube, free of tension and cracks, and powder Less, uniform grain shape; low purchase cost and preferential price.

Impact Crusher

Impact Crusher

Cone Crusher

Cone Crusher

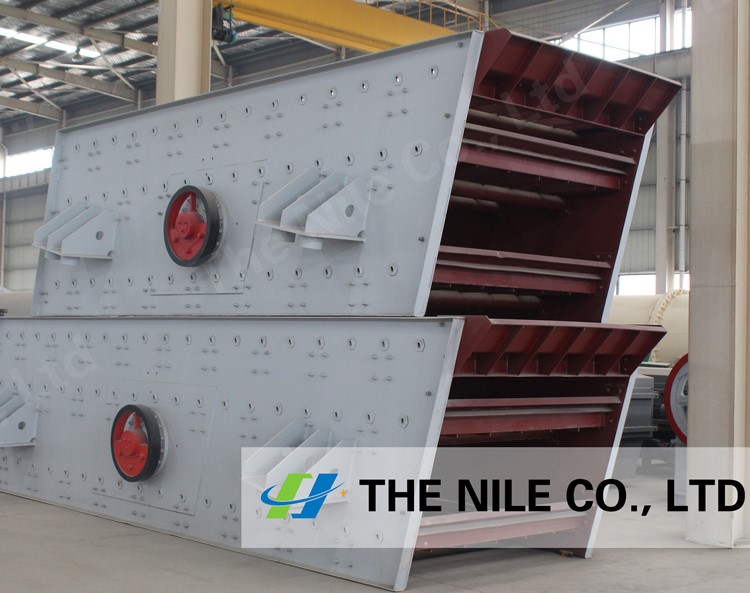

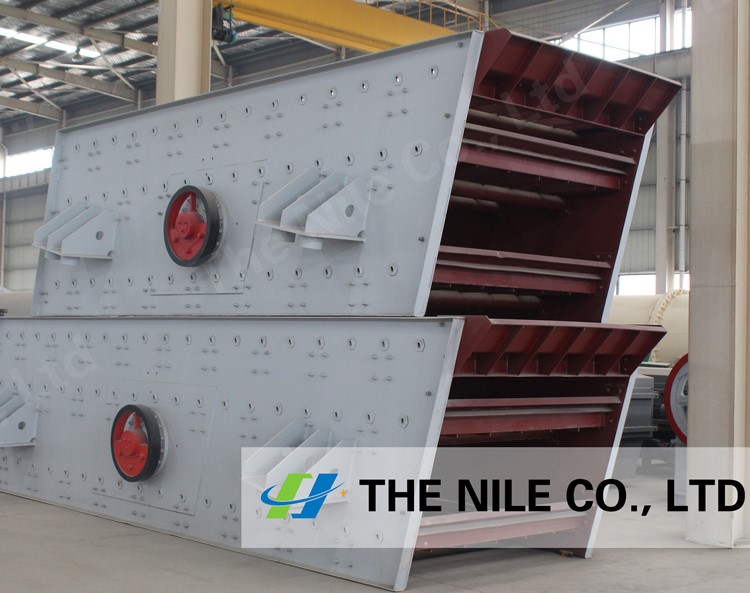

3. Screening-circular vibrating screen

The circular vibrating screen equipment is a new type of circular vibrating, multi-layer, high-efficiency vibrating screen. Vibrating screen supplier adopts cylindrical eccentric shaft vibration exciter and offset block to adjust the amplitude. There are many screening specifications, which not only has high screening efficiency, low vibration and noise, but also is durable and convenient for maintenance. Circular vibrating screen device can meet the requirements of users for different products and assembly.

Circular Vibrating Screen

Circular Vibrating Screen

Nile Company is a mining equipment manufacturer integrating production and sales. The products we produce are not only of good quality but also of good price. We always maintain a high-quality original intention, and continue to introduce advanced foreign technology to optimize our own equipment. High-quality service is our unchanging attitude, and you are welcome to consult for free.